Early Rankine steam engines employed simple expanders, powered by external heat sources. The type of fuel did not matter, but every part of the operation was inefficient.

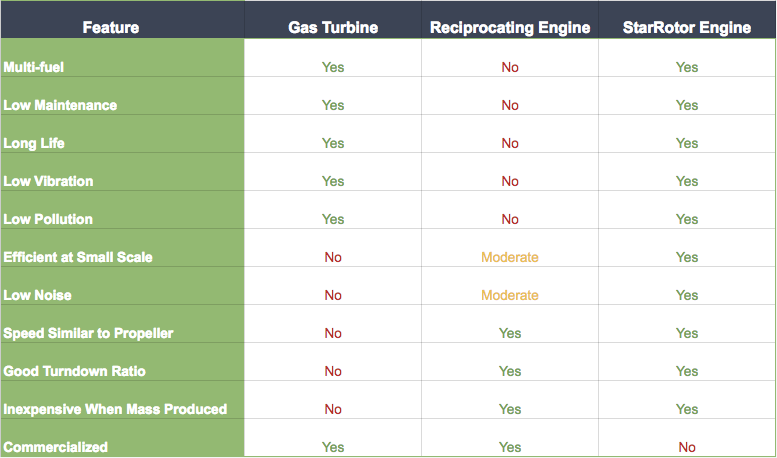

Otto and Diesel cycle internal combustion engines improve power density by using the same cylinders for compression, combustion, and expansion, at the cost of wasted heat energy, mechanical complexity, and increasingly stringent fuel requirements. Combustion efficiency suffers from the uneven temperature within the cylinder. The need to convert a complex mix of hydrocarbons into highly specified gasoline and diesel is a cost and efficiency penalty that flows all the way through the energy supply chain.

Brayton Cycle Engines

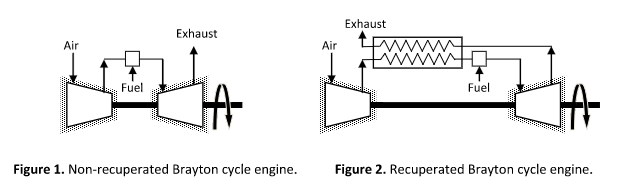

Brayton engines are most commonly used in jets, and in gas turbines for power generation. They feature continuous flow of air and fuel into and out of the combustion chamber at constant pressure, which allows them to achieve steady, efficient combustion at high rates. Overall efficiency is driven by the efficiency of their compressors and expanders, and by their handling of heat. For aircraft, smaller size and lower weight favor simple Brayton engines over recuperated versions. Ground-based units can take advantage of recuperation and multiple stages for greater efficiency.

As noted in the preceding compressor and expander sections, dynamic machines tend to require large scales and narrow operating windows to be efficient. They do not scale down well, and their efficiency falls off sharply when operated at lower speeds.

The high efficiency of StarRotor compressors and expanders enables Brayton cycle engines at scales much smaller than would be feasible with other technologies. Their smooth, efficient, purely rotational operation delivers high throughputs in a compact form, and their positive displacement flexibility allows them to maintain their efficiency over a much wider range of speeds and conditions than their turbine counterparts. Continuous combustion enables them to efficiently burn a wide range of fuels without the large heat losses and partially burned exhaust products that characterize internal combustion engines. These advantages make StarRotor's engine technology cleaner and more efficient than conventional technologies.